Custom Design

Built especially to fit your space

Fantastic Service

Exceptional service & quality

Dedicated Support

Experienced engineering team

Quality Assured

ISO 9001 quality assurance

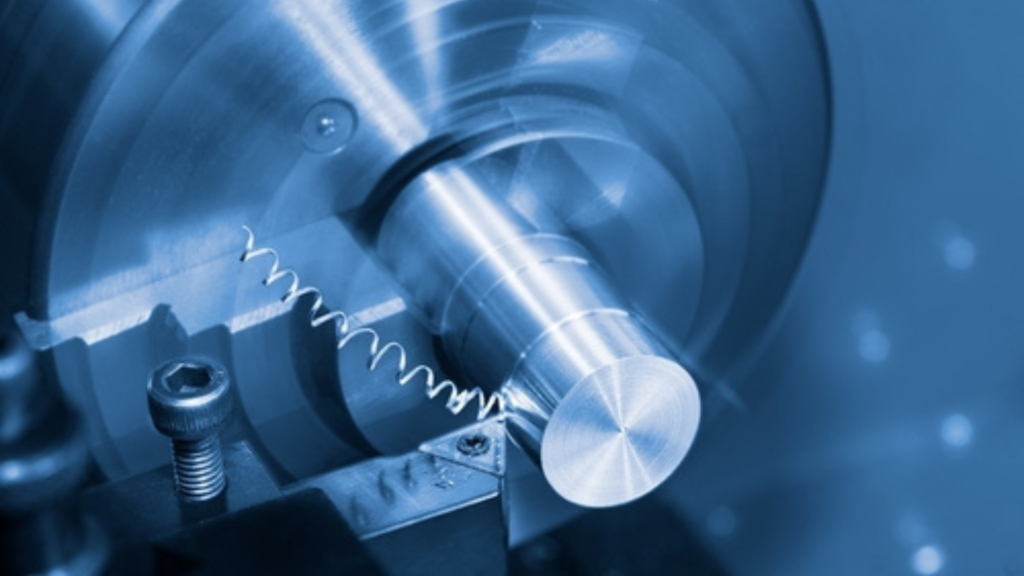

Metal Spinning Services

Shaw Metal Solutions is one of the UK’s leading metal spinners. One of the few metal spinning suppliers who can offer a full turnkey service, from in-house tooling to complete value-added metal fabrication.

Metal spinning, known as spin forming, is one of the oldest techniques. Combined with the latest CNC spinning equipment, it remains the ideal choice for various products and applications.

Metal spinning is often preferred due to the lower tooling costs and faster time to market compared to Die-casting, pressing or deep-drawing components.

The metal spinning process suits most metals, including mild steel, stainless steel, copper, brass, aluminium and specialist materials such as Inconel. Spun components can range from a few centimetres to several meters in diameter.

The diversity of materials and sizes, combined with other forming processes such as CNC punching, folding and welding, create tremendous scope for innovation, only limited by the laws of physics and the designer’s ingenuity.

Why Choose Shaw Metal?

We’ve partnered with hundreds of customers, supplying metal solutions to various applications. Solving problems and helping to achieve an optimum solution on time and budget. All are backed by ISO 9001 quality assurance.

Our dedicated design and engineering team are here to help. Providing design suggestions on new product concepts to advising on improvements to achieve the optimum volume manufacturing. We support 3D CAD design but are happy to work with simple sketches.

If you are frustrated with your existing supplier or need a fresh outlook to solve a manufacturing challenge, talk to us today.